Mortar Joint Selection

- By Tommy Bigham

- •

- 27 Aug, 2018

Recommended mortar joints for DecraStone

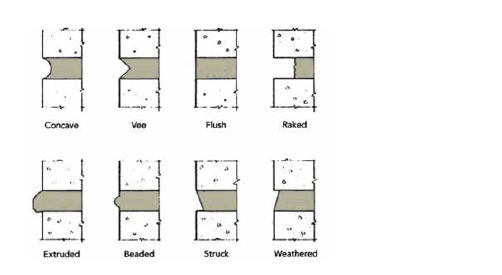

Understanding mortar joint types are essential to creating a weather tight building. The nine mortar joints discussed have had many decades of use. A recommended joint is one that we feel best fits our DecraStone concrete block use and installation.

A PDF of this blog is available on the Resources page

THE SPECIFICS OF MORTAR JOINTS

CONCAVE JOINT- This is the most common joint used in masonry construction. The tooling works the mortar tight into the joint to produce a more consistent weather joint. The pattern is emphasized and small irregularities in laying are concealed. Recommended.

V JOINT- Tooling works the mortar tight and provides a good weather tight joint. This shape is used to emphasize joints and conceal small irregularities in laying and provide a line in the center of the mortar joint. Recommended.

RAKED JOINT - This joint strongly emphasizes horizontal joints. It is however a very poor weather joint and is not recommended if exposed to weather. This mortar joint incorporates the ledge of the block to create the horizontal lines that are so desirable with this joint. The ledge is however a collector of rain water as it pours down the wall. Eventually the water will find its way around the mortar joint into the interior of the wall and building.

BEADED JOINT - A special effect joint in appearance. However, it is a poor exterior weather joint because of the exposed ledge and is not recommended.

STRUCK JOINT- This is used to emphasize horizontal joints. It is a poor weather joint and is not recommended as water will penetrate thru the lower edge of themortar.

GRAPEVINE JOINT- This shows a horizontal indentation and is used in wood mold brick installations typically. The joint creates a wavy line which replicates work that was done during America’s early years. It is a recommended joint.

EXTRUDED JOINT - Provides a rustic, high texture look. It can be satisfactory indoors or exterior fences or screen walls. It is not recommended for exterior building walls because the mortar is not compressed against the block or brick.

FLUSH JOINT- Use where the wall is to be plastered or where it is desirable to hide the mortar joints under paint. Since it is not compressed it can be difficult to make the joint weatherproof. The joint must be compressed to make the mortar come in complete contact with theblock. Not recommended.

WEATHERED JOINT- Used to emphasize horizontal joints. It is acceptable for weather resistance with the use of proper technique and the proper tool. Proper care must be taken to compress the joint. Possible recommend.

THE POSITIVES AND NEGATIVES OF TYPES OF MORTAR JOINTS

The type of mortar joint is important to the weather resis-tance of a building’s exterior walls. Proper technique and the proper tool will make all the difference in getting very acceptable and serviceable joints in masonry walls. The joints with ledges as noted below do not perform well in exterior building walls and will allow moisture penetration. Proper tooling will compact the mortar against the block or brick. Many conditions can exist that will not allow the mortar to properly compact though. They are conditional upon the mortar’s temperature, moisture content, depth of the bedding and head joint (they should befully bedded), the tool used, and the brick mason’s skill.

The durability of the masonry wall is dependent on quality and proper installation. Water will penetrate mortar that is not compressed properly thusly leaving a porous looking mortar texture. Water is even more likely to “leak” through small cracks that can form between the mortar and the block. If these conditions exist with cracks even as small as the thickness of a piece of paper then because of the differing atmospheric pressures within a building to that of the outdoors then water will actually be sucked toward the interior side of the block and will not stop till it finds an outlet usually directly through the wall or at the base of the wall and then directly onto the floor. Cracks in mortar cannot be allowed and the best way possible to prevent this wet condition is to properly “joint” the mortar.

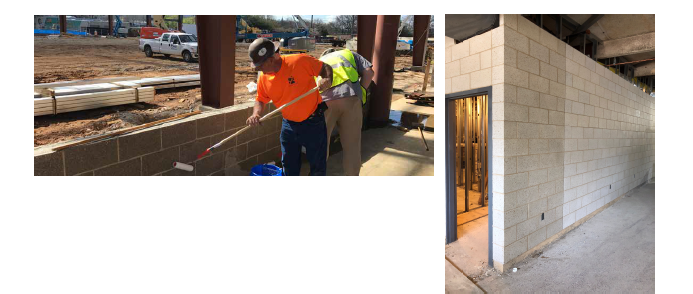

Proper cleaning techniques should always be followed to prevent the “blow out” of mortar joints when using the wrong type of pressure cleaning techniques.