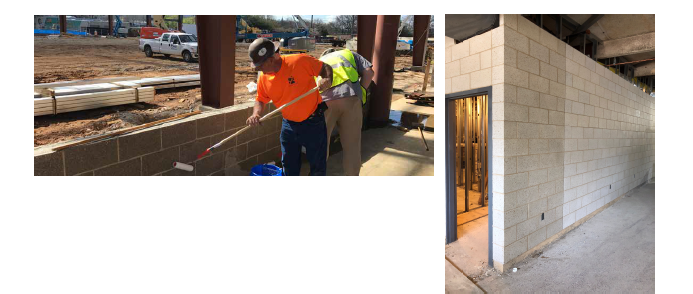

Sealing Ground Face

- By Tommy Bigham

- •

- 27 Aug, 2018

Important considerations for sealing DecraStone

A protective sealer on concrete masonry block can be usually be specified in situations where the color, ease of cleaning, protection from the elements may be a concern. This may apply to sealing either exterior or interior architectural concrete masonry. The post applied sealer must be compatible to the sealer that was applied to the DecraStone in plant. Best practices are to check with the producer of the DecraStone or view further information on the website for recommendations of sealer type.

A PDF copy of this blog is available on the Resource page.

WHY SEAL DECRASTONE ?

Provided the wall was constructed and cleaned properly it may not be necessary to add an additional coat of sealer. the DecraStone ground face cmu's have a coating of acrylic sealer applied at the factory. It may become a sacrificial coat if aggressive cleaning techniques are employed after installation.

INSTALLATION CONCERNS

To prevent water intrusion the latest generation integral water repellent is used in all DecraStone products. The same water repellent is also recommended for use in the mortar.

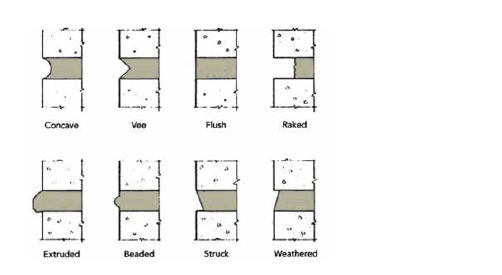

All mortar should be installed in accordance with its manufacturer’s recommendations. This includes the proper tooling of the joints, to insure a tight seal of the mortar against the block. Raking of the joints is not recommended because the mortar bond is enhanced through the use of a concave jointing tool. The best installed walls are not perfect.

A job applied masonry sealer is recommended as further insurance against water penetration that may occur through imperfections in the joints and masonry especially in single wyth walls (there is no backup wall with accompanying moisture barrier).

AESTHETIC ISSUES

Aggresive cleaning may remove the “sacrificial” in plant coat of sealer. DecraStone utilizes a high solids water base acrylic coating at the factory in order to prevent masonry staining. A daily wipe down of the walls can prevent the necessity of a heavy wall cleaning.

A final field coat of sealer, applied only after proper cleaning and drying of the wall, may be utilized to achieve a glossier finish.

As soon as possible after installation and cleaning of the masonry the entire wall should be sealed if that is determined to be necessary. This may help during the construction process to prevent job site damage.